Electrical control system

1. An independent electrical cabinet is equipped with air switches, relays and other electrical appliances.

2. For various alarm signals of the press, the limit switch and the press action realize program linkage.

3. Equipped with a centralized control panel with operation buttons and selection switches arranged on the panel.

Schneider is selected for electrical appliances, which are safe and reliable. The circuit lines of the switchboard are clear. The electrical schematic diagram is provided when the goods are delivered.

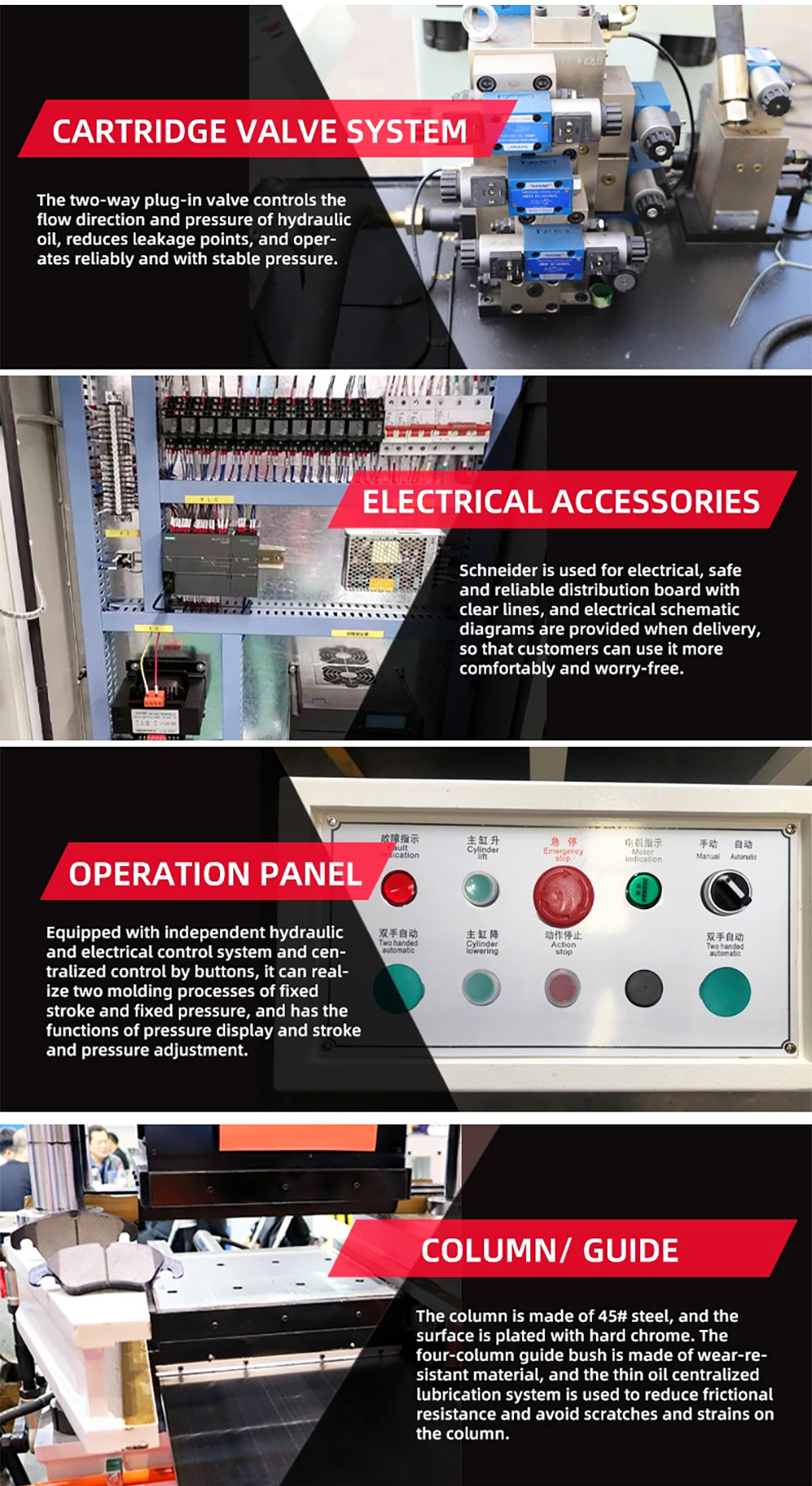

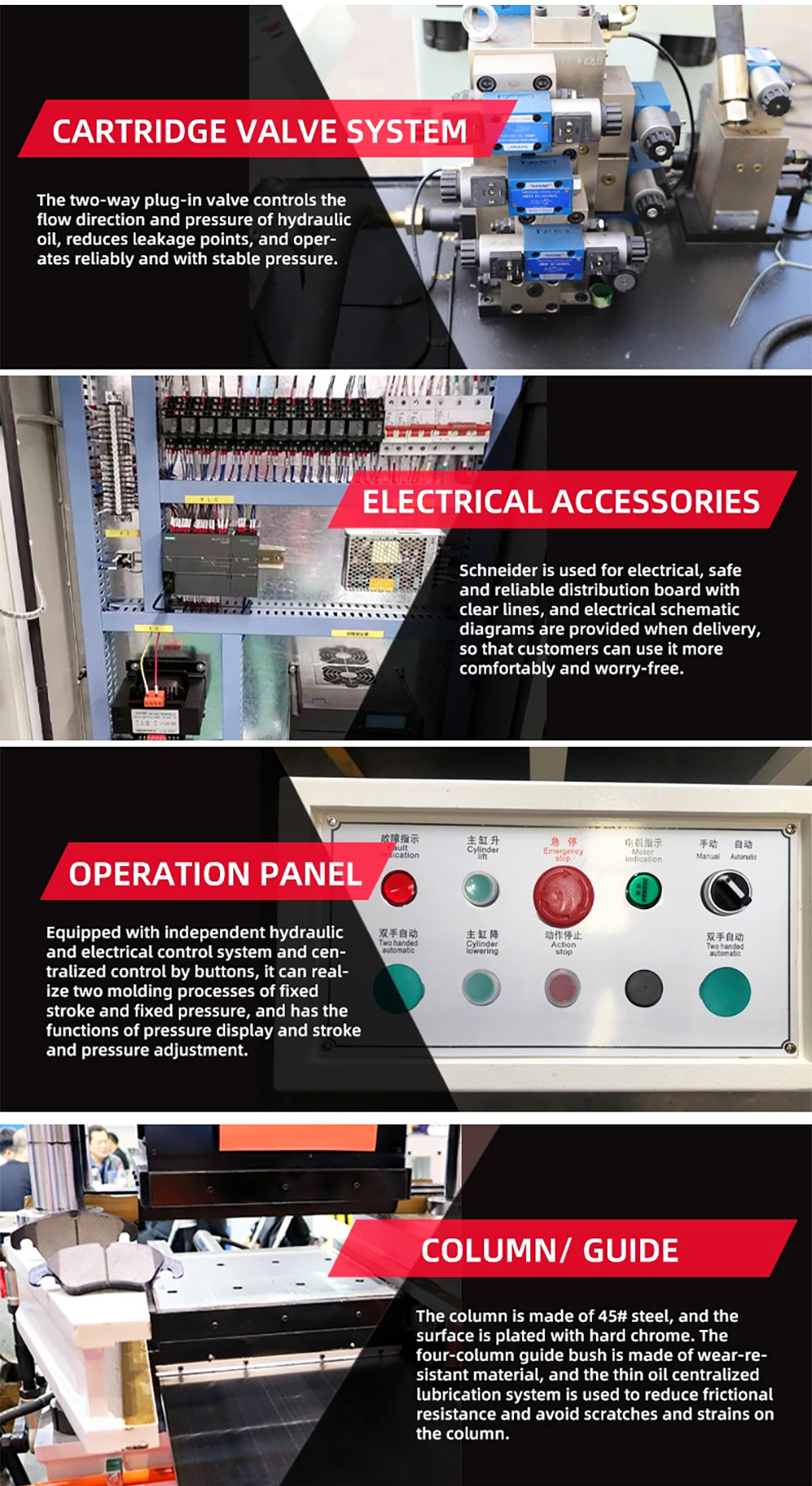

The two-way plug-in valve controls the flow direction and pressure of hydraulic oil, reduces leakage points, and operates reliably and with stable pressure.

OPERATION PANEL

Equipped with independent hydraulic and electrical control system and centralized control by buttons,it can realize two molding processes of fixed stroke and fixed pressure,

and has the functions of pressure display and stroke and pressure adjustment.

A control display screen is installed outside the electric box, the English interface can be adjusted.

Siemens PLC has the characteristics of high reliability, flexibility, and programmability, and can achieve precise control and monitoring of various industrial production processes.

| 200T | ||

| Nominal pressure(KN) | 2000 | |

| System pressure (Mpa) | 25 | |

| Maximum opening of indenter(mm) | 1200 | |

| Effective stroke of slider(mm) | 800 | |

| Effective size of table(mm) | Right and left(mm) | 900 |

| Front and back(mm) | 710 | |

| Throat deepth(mm) | 380 | |

| Effective size of indenter(mm) | 640*6400 | |

| Indenter velocity(mm/s) | Press head fast down speed(mm/s) | 170 |

| Press head feeding down speed(mm/s) | 6-16 | |

| Press head return speed(mm/s) | 150 | |

| Motor power(kw) | 11 | |

| Piston pump(ml/r) | 55 | |

| Max. Flow of hydraulic system(L/min) | ||

Electrical control system

1. An independent electrical cabinet is equipped with air switches, relays and other electrical appliances.

2. For various alarm signals of the press, the limit switch and the press action realize program linkage.

3. Equipped with a centralized control panel with operation buttons and selection switches arranged on the panel.

Schneider is selected for electrical appliances, which are safe and reliable. The circuit lines of the switchboard are clear. The electrical schematic diagram is provided when the goods are delivered.

The two-way plug-in valve controls the flow direction and pressure of hydraulic oil, reduces leakage points, and operates reliably and with stable pressure.

OPERATION PANEL

Equipped with independent hydraulic and electrical control system and centralized control by buttons,it can realize two molding processes of fixed stroke and fixed pressure,

and has the functions of pressure display and stroke and pressure adjustment.

A control display screen is installed outside the electric box, the English interface can be adjusted.

Siemens PLC has the characteristics of high reliability, flexibility, and programmability, and can achieve precise control and monitoring of various industrial production processes.

| 200T | ||

| Nominal pressure(KN) | 2000 | |

| System pressure (Mpa) | 25 | |

| Maximum opening of indenter(mm) | 1200 | |

| Effective stroke of slider(mm) | 800 | |

| Effective size of table(mm) | Right and left(mm) | 900 |

| Front and back(mm) | 710 | |

| Throat deepth(mm) | 380 | |

| Effective size of indenter(mm) | 640*6400 | |

| Indenter velocity(mm/s) | Press head fast down speed(mm/s) | 170 |

| Press head feeding down speed(mm/s) | 6-16 | |

| Press head return speed(mm/s) | 150 | |

| Motor power(kw) | 11 | |

| Piston pump(ml/r) | 55 | |

| Max. Flow of hydraulic system(L/min) | ||