| Availability: | |

|---|---|

| Quantity: | |

| Type Y41-40T | Unit | Value | |

| Nominal Pressure | KN | 400 | |

| System Pressure | MPa | 25 | |

| Slider Stroke | mm | 280 | |

| Maximum Opening Height | mm | 480 | |

| Effective Size of Workbench | The Lift and Right Sides | mm | 1500 |

| The Front and Rear Sides | mm | 500 | |

| Slider Speed | Idle Stroke | mm/s | 100 |

| Feeding | mm/s | 25 | |

| Back Tracking | mm/s | 50 | |

| Motor Power | KW | 3 | |

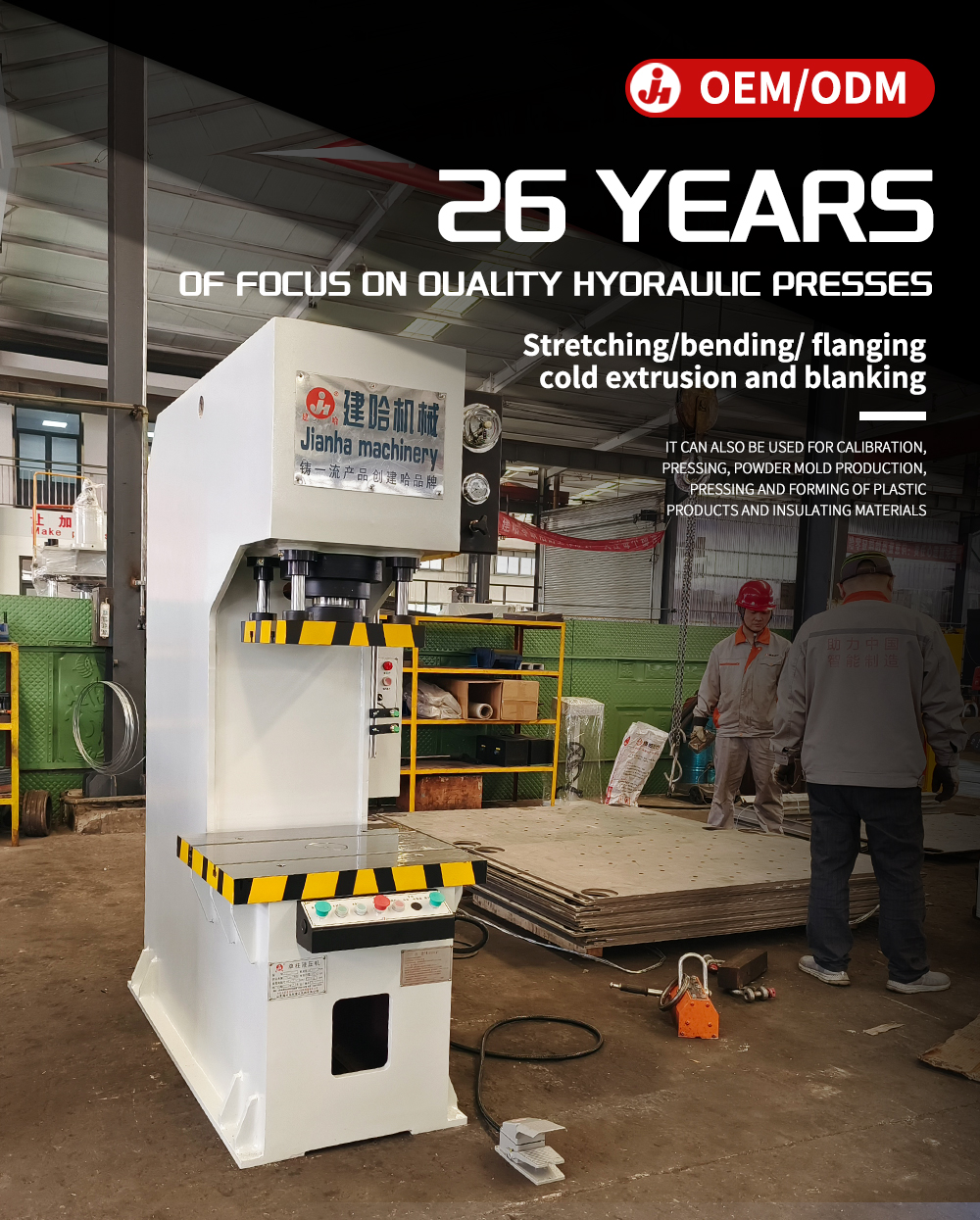

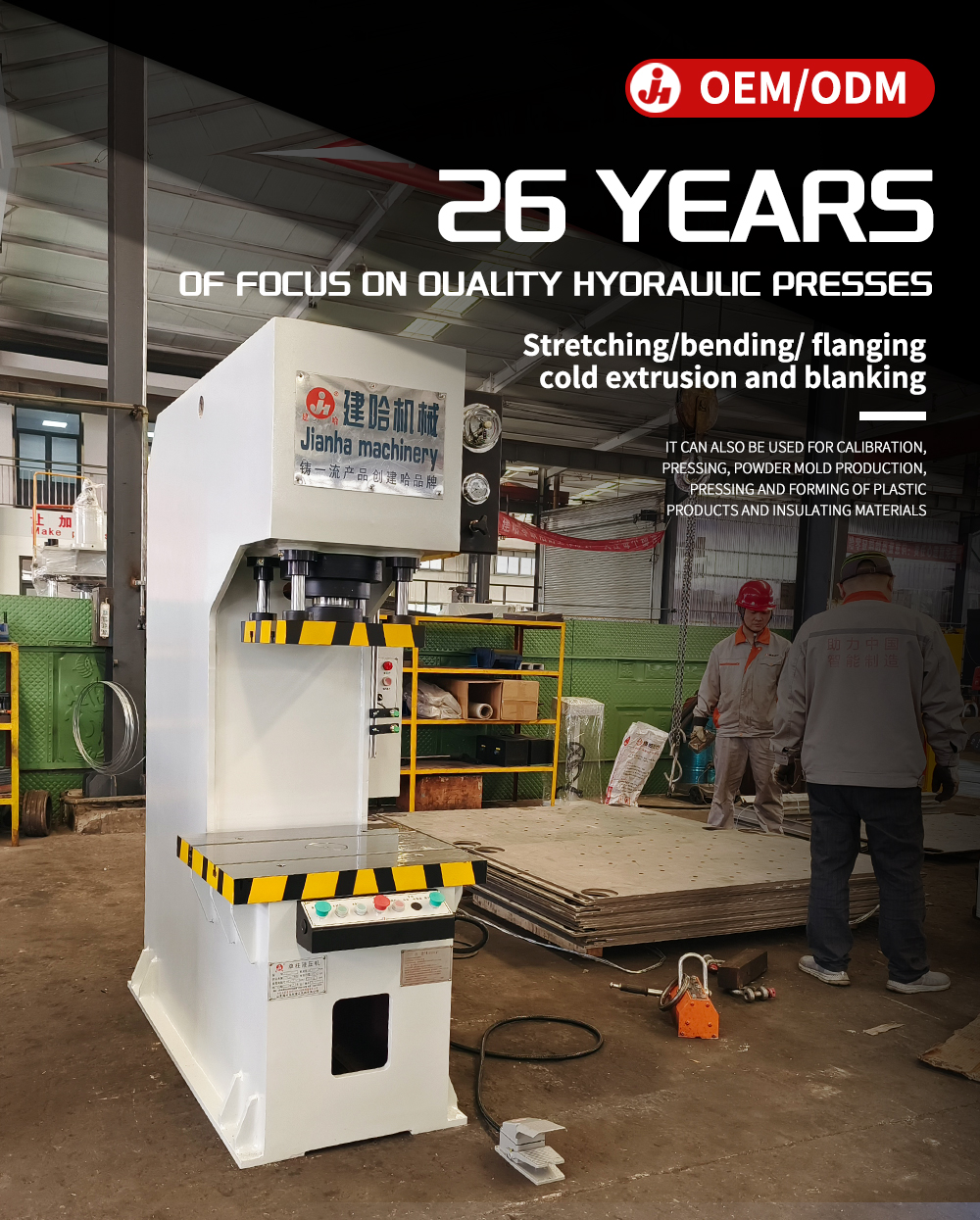

What are the main functions of the Y41 series hydraulic press?

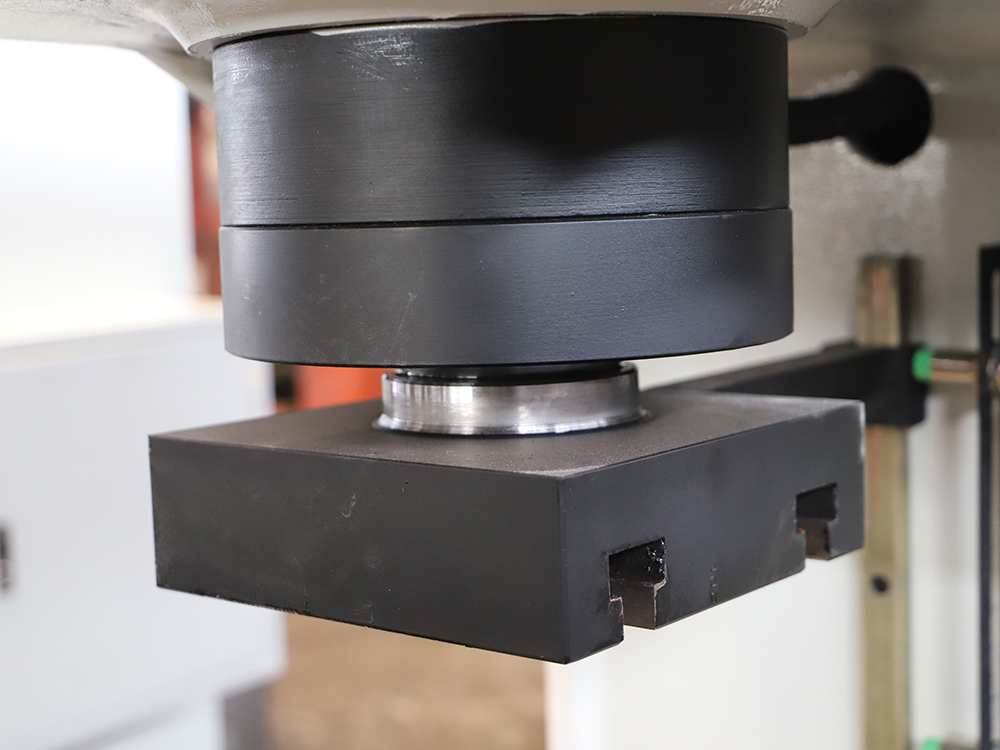

(1) Computer optimized design, C-shaped structure, simple, economical and practical.

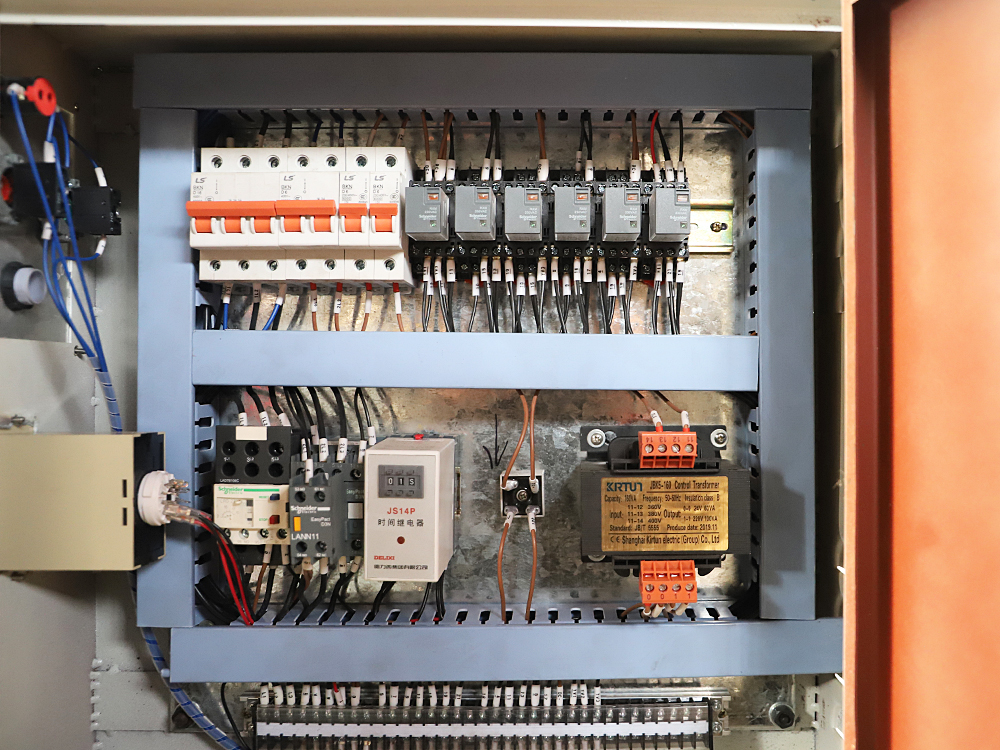

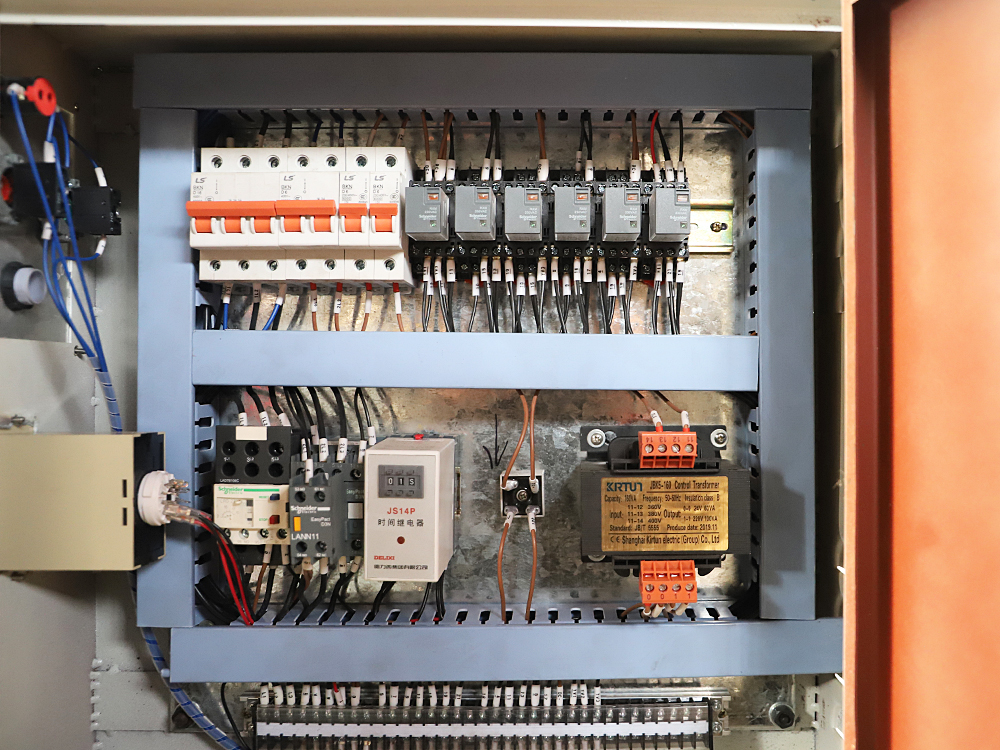

(2) The hydraulic control adopts the integrated system of electromagnetic reversing valve, which has reliable action, long service life, small hydraulic impact, and reduces the number of connecting pipelines and leakage points.

(3) The working pressure of the indenter and the range of the downward stroke can be adjusted according to the process requirements.

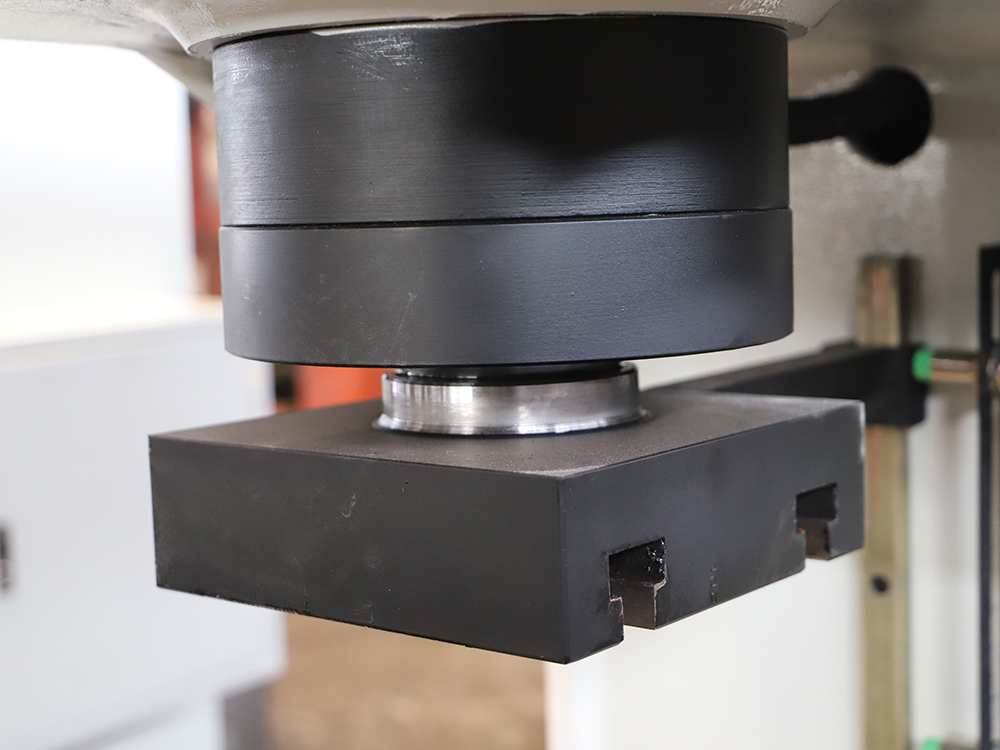

Structure overview of Y41 series hydraulic press?

The main application of Y41 series hydraulic press?

Three characteristics of Y41 series single-arm hydraulic press:

Q:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model . You can also

send us the products drawing ,we will choose the most suitable machines for you .

Q:Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province, China. You are warmly welcomed to visit our company

Q: How about your after-sale service?

A: Some operating problems can be solved with us online. Our engineers are also available to service overseas.

Q: What is your trade terms and payment terms?

A: FOB, CFR and CIF all acceptable. T/T、 L/C payment method.

| Type Y41-40T | Unit | Value | |

| Nominal Pressure | KN | 400 | |

| System Pressure | MPa | 25 | |

| Slider Stroke | mm | 280 | |

| Maximum Opening Height | mm | 480 | |

| Effective Size of Workbench | The Lift and Right Sides | mm | 1500 |

| The Front and Rear Sides | mm | 500 | |

| Slider Speed | Idle Stroke | mm/s | 100 |

| Feeding | mm/s | 25 | |

| Back Tracking | mm/s | 50 | |

| Motor Power | KW | 3 | |

What are the main functions of the Y41 series hydraulic press?

(1) Computer optimized design, C-shaped structure, simple, economical and practical.

(2) The hydraulic control adopts the integrated system of electromagnetic reversing valve, which has reliable action, long service life, small hydraulic impact, and reduces the number of connecting pipelines and leakage points.

(3) The working pressure of the indenter and the range of the downward stroke can be adjusted according to the process requirements.

Structure overview of Y41 series hydraulic press?

The main application of Y41 series hydraulic press?

Three characteristics of Y41 series single-arm hydraulic press:

Q:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model . You can also

send us the products drawing ,we will choose the most suitable machines for you .

Q:Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province, China. You are warmly welcomed to visit our company

Q: How about your after-sale service?

A: Some operating problems can be solved with us online. Our engineers are also available to service overseas.

Q: What is your trade terms and payment terms?

A: FOB, CFR and CIF all acceptable. T/T、 L/C payment method.