| Availability: | |

|---|---|

| Quantity: | |

| item | value |

| Slide Stroke (mm) | 550 |

| Machine Type | Four-column Three-beam Hydraulic Press |

| Ejector Force (kN) | 4000 |

| Return Force (kN) | 340kN |

| System | Servo |

| Condition | New |

| Place of Origin | China |

| Shandong | |

| Brand Name | Jianha |

| Year | 2023 |

| Voltage | 380V |

| Weight (T) | 12T |

| Model Number | Y32-400T |

| Motor Power (kw) | 22kw |

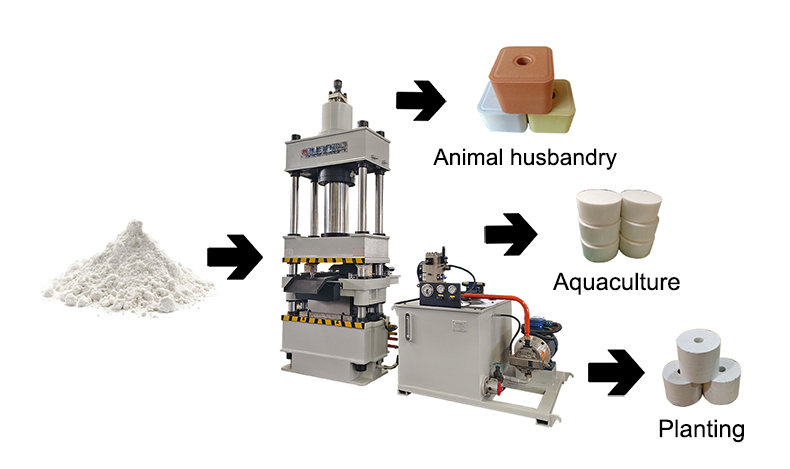

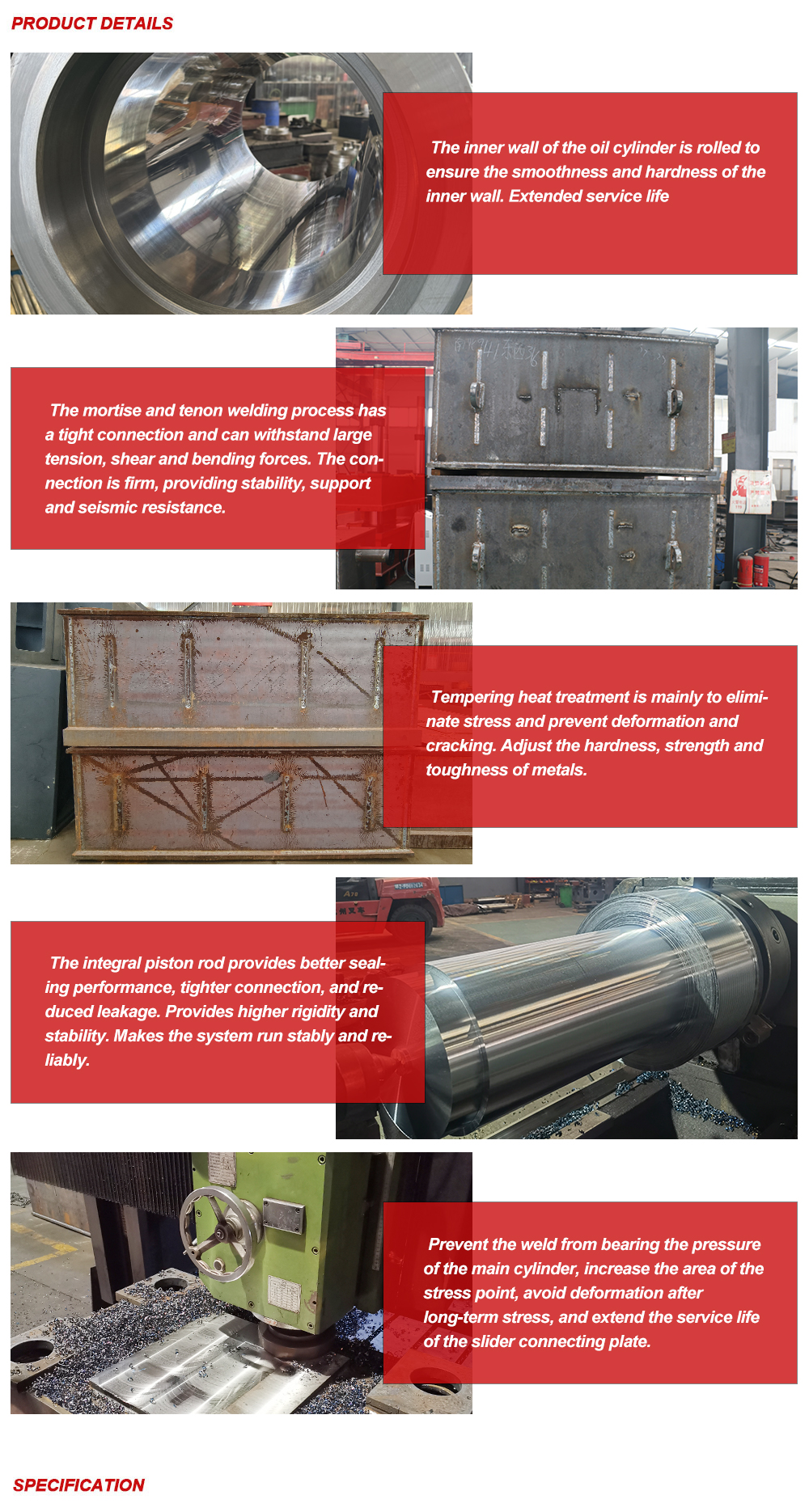

| Key Selling Points | Multifunctional |

| Warranty | 1 Year |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Advertising Company, Home Use, Energy & Mining, Other |

| Showroom Location | France, Germany, Viet Nam, Brazil, Saudi Arabia, Mexico, Russia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Romania, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan |

| Marketing Type | Hot Product 2023 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor, Pump, PLC, Other |

8. The stroke and pressure can be adjusted within specific range.

| item | value |

| Slide Stroke (mm) | 550 |

| Machine Type | Four-column Three-beam Hydraulic Press |

| Ejector Force (kN) | 4000 |

| Return Force (kN) | 340kN |

| System | Servo |

| Condition | New |

| Place of Origin | China |

| Shandong | |

| Brand Name | Jianha |

| Year | 2023 |

| Voltage | 380V |

| Weight (T) | 12T |

| Model Number | Y32-400T |

| Motor Power (kw) | 22kw |

| Key Selling Points | Multifunctional |

| Warranty | 1 Year |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Advertising Company, Home Use, Energy & Mining, Other |

| Showroom Location | France, Germany, Viet Nam, Brazil, Saudi Arabia, Mexico, Russia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Romania, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan |

| Marketing Type | Hot Product 2023 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor, Pump, PLC, Other |

8. The stroke and pressure can be adjusted within specific range.