| Technical parameters | Y32-315T |

| Nominal pressure(KN) | 3150 |

| System pressure(Mpa) | 25 |

| Maximum opening height(mm) | 700 |

| Maximum slider stroke | 600 |

| Effective size of workbench(mm) | 800(The front&rear sides) |

| Effective size of workbench(mm) | 800(The left&right sides) |

| idle stroke speed(mm/s) | 180 |

| Feeding speed(mm/s) | 6/19 |

| Back tracking speed(mm/s) | 160 |

| Plunger pump(L) | 100 |

| Play materials aperture(mm) | 60 |

| Slot(mm) | 50/150 |

| Dimensions of worktable to floor(mm) | 800 |

| Master cylinder bore(mm) | 400 |

| Four column diameter | 130 |

| Note:1. Mold fixing mode: T row groove (four straight grooves) on the working table; 2. Safety protection: grating protection; 3. With mechanical feeding device; 4. Controlled by PLC operation | |

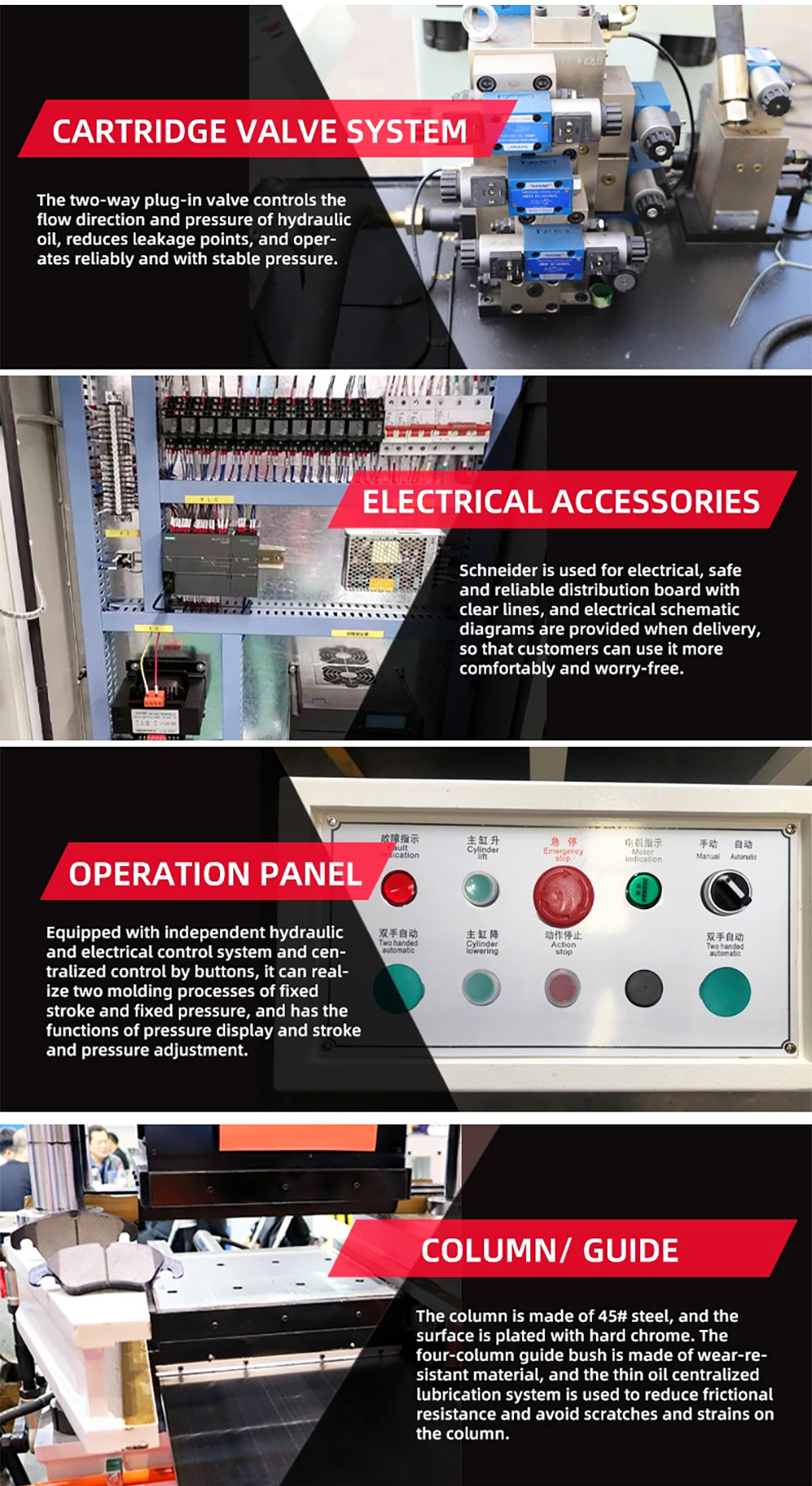

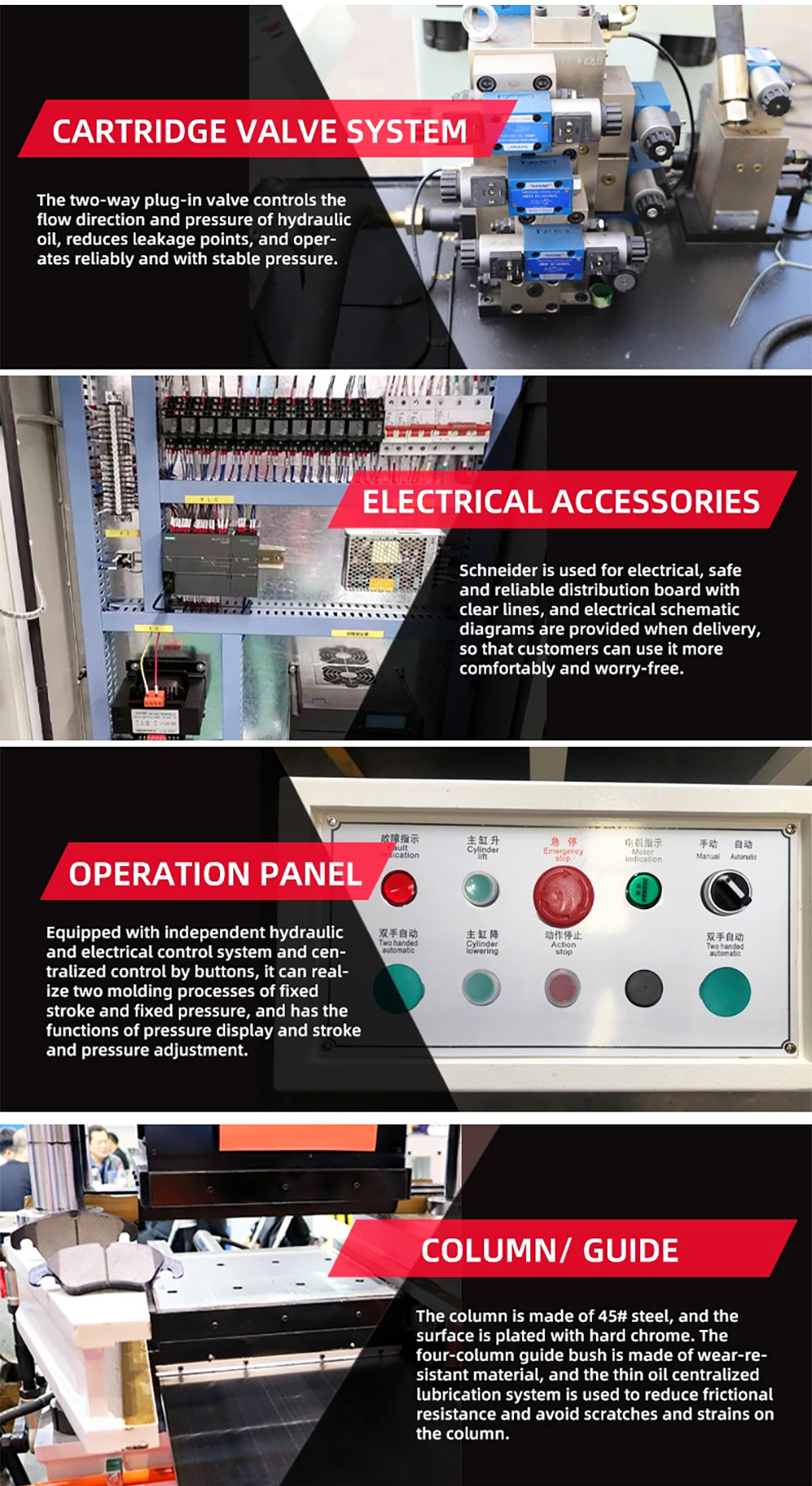

3 beam 4 column structures, economical and Practical ,Hydraulic control adopt insert type compact valve system,with reliable operation,long service life,minimized hydraulic shock, minimized duct connection and possibleleak point. Two operation model, pressure regulation and stroke regulation which can be selected through operational panel,and has the character of pressure-keeping and time-delaying, Delay time is adjustable, working pressure and stroke can be adjusted within the prescribed scope . Adopting centralized control buttons, with both manual and semi-automatic operation mode.

| Technical parameters | Y32-315T |

| Nominal pressure(KN) | 3150 |

| System pressure(Mpa) | 25 |

| Maximum opening height(mm) | 700 |

| Maximum slider stroke | 600 |

| Effective size of workbench(mm) | 800(The front&rear sides) |

| Effective size of workbench(mm) | 800(The left&right sides) |

| idle stroke speed(mm/s) | 180 |

| Feeding speed(mm/s) | 6/19 |

| Back tracking speed(mm/s) | 160 |

| Plunger pump(L) | 100 |

| Play materials aperture(mm) | 60 |

| Slot(mm) | 50/150 |

| Dimensions of worktable to floor(mm) | 800 |

| Master cylinder bore(mm) | 400 |

| Four column diameter | 130 |

| Note:1. Mold fixing mode: T row groove (four straight grooves) on the working table; 2. Safety protection: grating protection; 3. With mechanical feeding device; 4. Controlled by PLC operation | |

3 beam 4 column structures, economical and Practical ,Hydraulic control adopt insert type compact valve system,with reliable operation,long service life,minimized hydraulic shock, minimized duct connection and possibleleak point. Two operation model, pressure regulation and stroke regulation which can be selected through operational panel,and has the character of pressure-keeping and time-delaying, Delay time is adjustable, working pressure and stroke can be adjusted within the prescribed scope . Adopting centralized control buttons, with both manual and semi-automatic operation mode.