| Availability: | |

|---|---|

| Quantity: | |

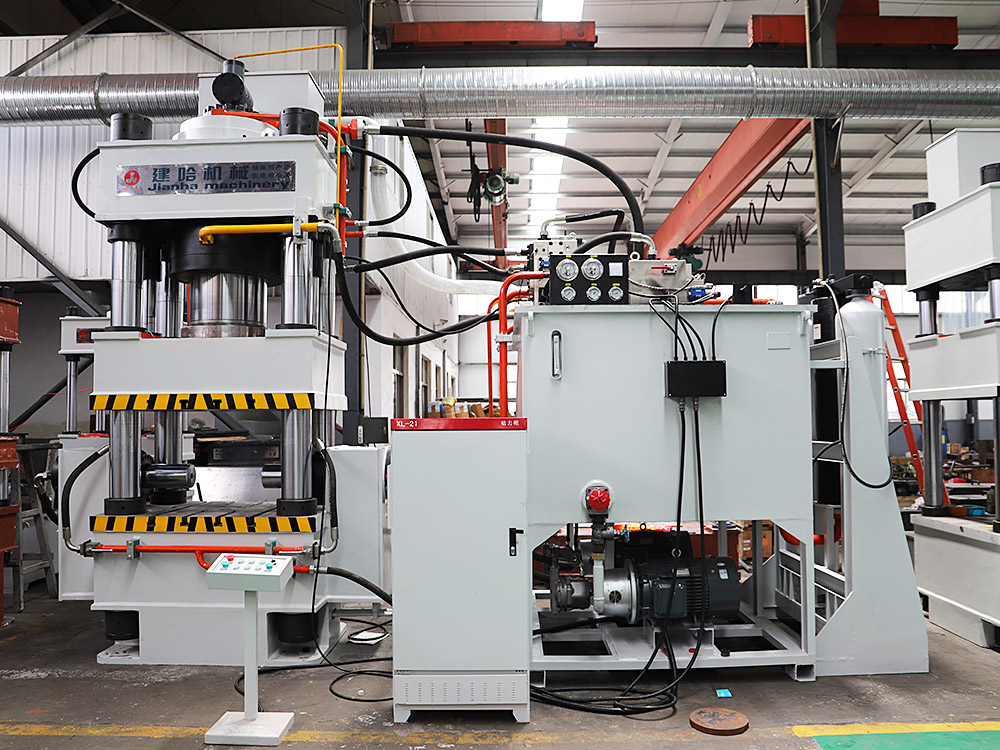

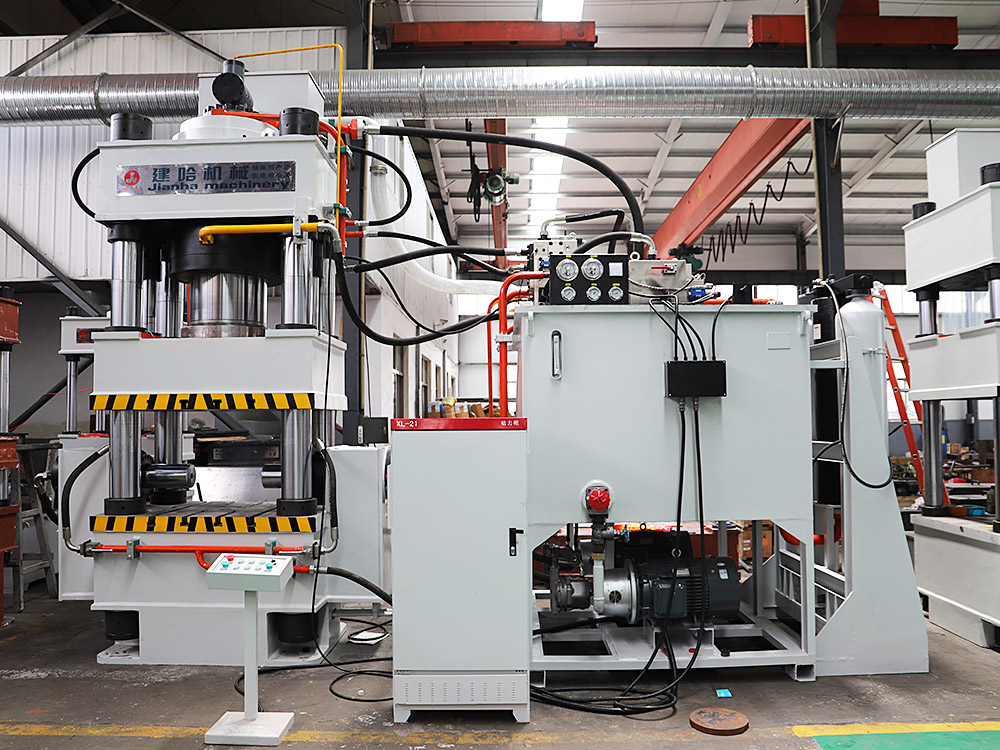

The electrical control system adopts "PLC" programmable controller, which improves the reliability of the electrical control system, realizes the accurate control of the speed, pressure and pressure classification of the forging hydraulic press, and easily realizes the chain control of the forging hydraulic press and auxiliary equipment. The die forging hydraulic press can be equipped with a mobile worktable, which is convenient for users to replace the die.

Die forging hydraulic press adopts advanced forging and high-precision forming equipment, and has a wide range of application processes, including multi-directional extrusion, upsetting, punching, closed die forging, etc. It can realize various functions such as fast forging, constant forging, and pressure holding; it meets the requirements of forging processes such as upsetting, drawing, punching, horse bar reaming, and staggering. It is mainly suitable for the forging production of all kinds of specialruler forgings, shafts, discs, and special-shaped parts, such as bearing inner rings, flanges, half shafts, joints, cross heads,wheel hubs, train wheels, etc.

| item | value |

| Slide Stroke (mm) | 500 |

| Ejector Force (kN) | 300*2 |

| Return Force (kN) | 800kN |

| System | Servo |

| Condition | New |

| Place of Origin | China |

| Shandong | |

| Brand Name | JIANHA BAOFA |

| Year | 2023 |

| Voltage | 220V/380V/415V |

| Dimension(L*W*H) | 3205*1630*1240mm |

| Weight (T) | 21.5T |

| Model Number | Y32-630TC |

| Motor Power (kw) | 44kw |

| Key Selling Points | High-accuracy |

| Warranty | 1 years |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Energy & Mining, Construction works |

| Showroom Location | Mexico, Russia, South Korea, Colombia, South Africa, None |

| Marketing Type | Hot sale |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 years |

| Core Components | Motor, Pump, Engine |

| Type | 4 Columns |

| Power souce | Electricity Hydraulic Power |

| Machine Type | Y32 630T |

| Suitable for | Metal hot die forging |

| Color | Costomized |

| Y32 Models | Unit | 630TXC | 800TXC | 1000TXC | ||

| Nominal Pressure | KN | 6300 | 8000 | 10000 | ||

| System Pressure | MPa | 25 | 25 | 25 | ||

| Slider Stroke | mm | 750 | 500 | 700 | ||

| Maximum Opening Height | mm | 1350 | 900 | 900 | ||

| Effective Size of Workbench | The Lift and Right Sides | mm | 1400 | 1400 | 1600 | |

| The Front and Rear Sides | mm | 1400 | 1240 | 1600 | ||

| Slider Speed | Idle Stroke | mm/s | 170 | 150 | 160 | |

| Feeding | mm/s | 5/15 | 6/15 | 6/15 | ||

| Back Tracking | mm/s | 120 | 150 | 200 | ||

| Cushion output | T | 315 | 400 | 500 | ||

| Cushion ejection stroke | mm | 350 | 400 | 300 | ||

| Motor Power | KW | 22*2 | 30*2 | 30*2 | ||

The electrical control system adopts "PLC" programmable controller, which improves the reliability of the electrical control system, realizes the accurate control of the speed, pressure and pressure classification of the forging hydraulic press, and easily realizes the chain control of the forging hydraulic press and auxiliary equipment. The die forging hydraulic press can be equipped with a mobile worktable, which is convenient for users to replace the die.

Die forging hydraulic press adopts advanced forging and high-precision forming equipment, and has a wide range of application processes, including multi-directional extrusion, upsetting, punching, closed die forging, etc. It can realize various functions such as fast forging, constant forging, and pressure holding; it meets the requirements of forging processes such as upsetting, drawing, punching, horse bar reaming, and staggering. It is mainly suitable for the forging production of all kinds of specialruler forgings, shafts, discs, and special-shaped parts, such as bearing inner rings, flanges, half shafts, joints, cross heads,wheel hubs, train wheels, etc.

| item | value |

| Slide Stroke (mm) | 500 |

| Ejector Force (kN) | 300*2 |

| Return Force (kN) | 800kN |

| System | Servo |

| Condition | New |

| Place of Origin | China |

| Shandong | |

| Brand Name | JIANHA BAOFA |

| Year | 2023 |

| Voltage | 220V/380V/415V |

| Dimension(L*W*H) | 3205*1630*1240mm |

| Weight (T) | 21.5T |

| Model Number | Y32-630TC |

| Motor Power (kw) | 44kw |

| Key Selling Points | High-accuracy |

| Warranty | 1 years |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Energy & Mining, Construction works |

| Showroom Location | Mexico, Russia, South Korea, Colombia, South Africa, None |

| Marketing Type | Hot sale |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 years |

| Core Components | Motor, Pump, Engine |

| Type | 4 Columns |

| Power souce | Electricity Hydraulic Power |

| Machine Type | Y32 630T |

| Suitable for | Metal hot die forging |

| Color | Costomized |

| Y32 Models | Unit | 630TXC | 800TXC | 1000TXC | ||

| Nominal Pressure | KN | 6300 | 8000 | 10000 | ||

| System Pressure | MPa | 25 | 25 | 25 | ||

| Slider Stroke | mm | 750 | 500 | 700 | ||

| Maximum Opening Height | mm | 1350 | 900 | 900 | ||

| Effective Size of Workbench | The Lift and Right Sides | mm | 1400 | 1400 | 1600 | |

| The Front and Rear Sides | mm | 1400 | 1240 | 1600 | ||

| Slider Speed | Idle Stroke | mm/s | 170 | 150 | 160 | |

| Feeding | mm/s | 5/15 | 6/15 | 6/15 | ||

| Back Tracking | mm/s | 120 | 150 | 200 | ||

| Cushion output | T | 315 | 400 | 500 | ||

| Cushion ejection stroke | mm | 350 | 400 | 300 | ||

| Motor Power | KW | 22*2 | 30*2 | 30*2 | ||